![]() Zenyatta Ventures Ltd. {TSX.V: ZEN}

Zenyatta Ventures Ltd. {TSX.V: ZEN}

Provided a report on progress in the 81 research partnerships that it has entered into since 2013 that are creating increasing demand for Albany graphite as a source material

Due to this growing demand, the company has applied for a bulk sample permit to collect up to 990 tonnes of Albany Graphite mineralisation to support Zenyatta’s many collaborative industrial and university research initiatives.

.

.

Zenyatta Ventures applies for bulk sample permit

2018-09-04 06:21 ET – News Release

Dr. Francis Dube reports

ZENYATTA REPORTS ON GRAPHENE RESEARCH PROGRESS

.

.

Zenyatta Ventures Ltd. {TSX.V: ZEN} has provided a report on progress in the 81 research partnerships that it has entered into since 2013 that are creating increasing demand for Albany graphite as a source material for graphene and graphene oxide as well as high-purity graphite for new markets such as energy storage.

.

Due to this growing demand, the company has applied for a bulk sample permit to collect up to 990 tonnes of Albany Graphite mineralization to support Zenyatta’s many collaborative industrial and university research initiatives.

.

On the day of the special meeting, May 11th 2018, Zenyatta had entered into a total of 70 collaborative research agreements, 25 of which were with Academic institutions while 55 were with industry partners. A number of the research agreements signed by the previous management had expired or become inactive due to a lack of contact in the last year.

.

Since the special meeting, the Company has accelerated its outreach with the addition of three new members to the team focused on graphene research and product development. Since then, the Company has already entered into 11 new industrial partnerships with interest in concrete, auto parts, coatings, as well as applications in defense and aerospace technology. These industry partners are all potential customers for graphene products derived from Albany Graphite.

.

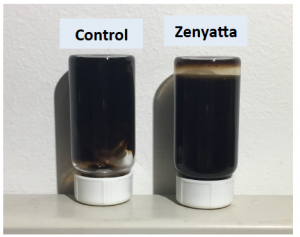

Zenyatta has now received expressions of interest in off-take from four companies for its high-purity Albany Graphite as a precursor material for graphene production. Dr. Francis Dube Co-CEO noted “Zenyatta’s unique Albany Graphite has been shown by multiple academic institutions including Sussex University and Ben-Gurion University to exfoliate more easily with higher yields of mono-layer to tri-layer graphene. This has attracted interest from other graphene producers to work with Albany Graphite.”

.

Recent research at Tokyo Technical University led by Professor Arao and his team has shed light on why Albany Graphite is so well-suited for making graphene. Dr. Arao concluded that graphite with very small crystal sizes (less than 200 nanometres) is much more easily exfoliated (or converted) to produce graphene, as less fragmentation energy is required to separate the individual graphene sheets. Albany Graphite exfoliates more easily than flake graphite due to its inherent small crystal size which is related to how the deposit was formed.

.

Zenyatta’s Vice-President, Peter Wood, P.Eng. P.Geo. noted, “at Albany, the graphite mineralisation was essentially {A ‘}flash frozen’ to form fine graphite crystallites due to the relatively rapid volcanic eruptive process under which the deposit formed. This does not occur with flake graphite which forms through a much slower process of recrystallisation of organic carbonaceous material during regional metamorphism resulting in the growth of much larger graphite crystals.”

.

The research collaboration with Dr. Regev of Ben-Gurion University (“BGU”) and Lariplast on the addition of graphene and graphene oxide into concrete, reported in the Company’s news release dated February 1, 2018 , had to be put on hold as BGU required larger amounts of samples derived from Albany Graphite than was available at the time.

.

This work yielded very encouraging results and will resume once more graphite sample material becomes available from new process development work. Additional encouraging research work on the concrete additive opportunity is currently being undertaken at the University of Toronto. Results will be reported on as they become available.

.

The research collaboration with Ballard Power Systems, Inc. (T: BLDP) has also produced encouraging results, including documentation of the excellent high temperature tolerance of Albany graphite versus Ballard’s baseline reference graphite. It was reported that 40% of Albany graphite withstood temperatures of 1000 degree C compared to Ballard’s baseline reference graphite which had completely disintegrated at 860 degree C. This high thermal tolerance of Albany Graphite has led to interest for several specific applications that are now being studied by a number of research groups.

.

A research partnership with an advanced material company based in the United States developing a next generation battery product, has also yielded very encouraging preliminary results. The next step in this partnership involved Zenyatta supplying a larger sample of graphene oxide which unfortunately could not be supplied at the time due to lack of product in inventory. Zenyatta will renew this research when the bulk sample work and graphene oxide production scale-up has been completed.

.

Zenyatta continues to receive significant interest for collaborations on research for new graphene and graphene oxide product applications from Albany Graphite with both industry and academic partners.

.

Mr. Peter Wood, P.Eng, P.Geo., Vice President of Zenyatta, is the “Qualified Person” for the purposes of National Instrument 43-101 and has reviewed, prepared and supervised the preparation of the technical information contained in this news release.

.

.

About Zenyatta Ventures Ltd

Zenyatta’s Albany Graphite Project hosts a large and unique quality deposit of highly crystalline graphite. Independent labs in Japan, UK, Israel, USA and Canada have demonstrated that Zenyatta’s Albany Graphite/Naturally PureTM easily converts (exfoliates) to graphene using a variety of simple mechanical and chemical methods. The deposit is located in northern Ontario just 30km north of the Trans-Canada Highway, near the communities of Constance Lake First Nation and Hearst. Important nearby infrastructure include hydro-power, natural gas pipeline, a rail line 50 km away and an all-weather road just 10 km from the deposit.

.

We seek Safe Harbor.